Endless diamond wire is a powerful and trusted tool that many industries use to cut sapphire and other tough crystals. It is made to give smooth, clean, and delicate cuts while creating less waste and lasting for a long time. Many people like it because it is safe, strong, and saves money. It is used in labs, factories, and large projects worldwide.

Diamond wire is not only for sapphire but also for silicon, solar wafers, graphite, and other hard materials. This tool allows workers to cut fast, cut safely, and get excellent results. In this guide, we will explain in easy words why Diamond wire is so important, how it is made, and where it is used, so people of all ages can understand.

Why Endless Diamond Wire Is Vital for Sapphire

Sapphire is one of the hardest crystals and is very hard to cut. Regular blades break fast, wear out quickly, and leave rough and messy edges. The endless-diamond wire for sapphire cutting is made to stay sharp, strong, and steady during long work hours. It cuts smoothly and gives clean edges that need minor fixing later. This makes it very useful when making watch glass, LED parts, phone screens, and optical glass. Without diamond wire, the cutting process would be slower, cost more, and riskier. With diamond wire, factories can finish more work quickly and spend less money on polishing. This is why infinite diamond wire is now the top choice when working with sapphire.

Endless Diamond Wire Saw Machines for Industry

The diamond wire saw machine is built for hard, busy work in labs and factories. It keeps a steady force on the wire so every cut stays smooth, safe, and even. It works well for both thick cuts and skinny slices. It has become one of the most used machines in plants that work with sapphire, silicon, and other crystals. These machines have smart controls for speed, tension, and cooling. This helps protect the wire and makes it last longer. This machine is the heart of production for many factories because it can run for many hours without stopping while still giving clean and stable results.

Endless Diamond Wire for Solar Wafers

Solar makers need thin, clean, and even slices of silicon. The endless wire for solar wafers makes this easy because it cuts fast and wastes very little. It helps lower the cost of making solar cells and makes them work better. Panels made with this tool last longer and give more energy. Endless-wire has changed how solar wafers are made because it can cut more slices from each silicon block. Smooth and clean cuts also make it easy to build high-performance solar cells. For small and large solar companies, endless diamond-wire is now a tool they must have.

Endless Diamond Wire Slicing Equipment

Endless diamond-wire slicing equipment is essential for tough cutting jobs requiring accuracy and clean results. It gives smooth cuts with less heat, keeping the tool and the material safe. These machines are made to run for long hours without a break, making them perfect for the mass production of gems, glass, silicon, and crystals. They are easy to use and easy to take care of, which saves time for workers. Since they produce less heat and less waste, the costs of cooling and cleaning are lower. This is why more industries are now using diamond wire slicing equipment.

Industrial Endless Diamond Wire Cutting Tool

The industrial diamond wire cutting tool is built for tough jobs like stone, glass, and crystals. It is safe, steady, and suitable for bulk cutting work. Many industries trust it because it lasts long and gives fine and clean cuts. This tool can be used for small parts as well as large blocks. The wire is strong but flexible, handling long jobs without breaking. This tool is one of the best for builders, labs, and factories when they need both speed and safety.

How Endless Diamond Wire Is Made

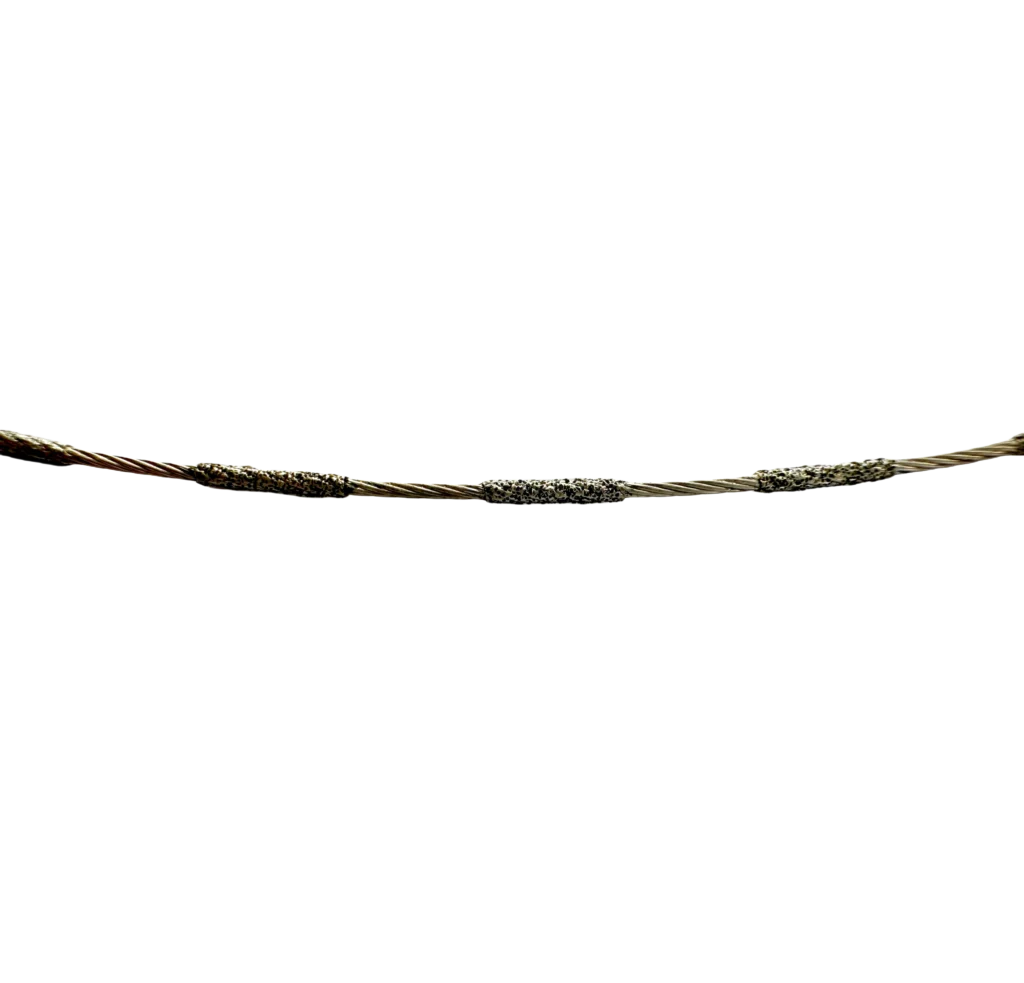

The endless-diamond wire manufacturing process uses modern technology and careful steps. First, fine diamond grit is placed on a strong wire. Then, it is bonded, coated, and heated to stick tight. Each wire is tested to ensure it is sharp, strong, and safe. Makers check the size, bond strength, and sharpness before sending it to customers. Because of this careful work, diamond wires are trusted in labs, factories, and industries worldwide.

Endless Diamond Wire Saw for Silicon

Silicon is used in chips, solar cells, and many tech products. The endless-diamond wire saw for silicon cuts clean, reduces cracks, and makes less waste. It is now widely used in chip and semiconductor factories. This tool helps companies get better wafers, spend less, and profit more. Clean silicon cuts are essential for making chips that run fast and safely. Endless wires also make cutting silicon ingots into wafers for solar panels and electronics easier. Because of its sharpness and speed, it has become a top choice in high-tech industries.

Low-Cost Endless Diamond Wire

Not all projects need costly wires. The low-cost diamond wire is made for schools, small labs, and start-ups. It cuts clean while being much cheaper. Even at a lower price, these wires are still safe and reliable. They are a wise choice for learning, practice, and small jobs. By giving affordable options, makers ensure everyone can use good tools without spending too much money.

Best Endless Diamond Wire Suppliers

Buying from the best diamond wire suppliers is essential for the best results. Good suppliers give wires that last long, cut fast, and stay safe. One trusted name is Vimfun. They make many types of cables and provide support to help clients choose the right one. Buying from a good supplier means a good product and good service. Vimfun is trusted worldwide for cutting sapphire, solar wafers, silicon, and graphite.

Special Diamond Wires for Graphite Cutting

Full-Coated Endless Wire

The Full-Coated Endless Wire for Graphite Cutting has a full-coated design that helps it stay cool and smooth. This design stops clogging and improves cutting speed. It is often used for cutting graphite blocks, rods, and plates because it gives fine cuts with less dust.

Segment Coated Diamond Wire Loop

The Segment Coated Diamond Wire Loop for Graphite Cutting has small spaces that let dust move out. This keeps the cut cool and smooth, even during long jobs. It is widely used in mold-making and carbon work. Because it stays calm and safe, many industries pick it for huge projects.

Thread Coated Diamond Wire Loop

The Thread Coated Diamond Wire Loop is another safe and trusted choice. It is valued for its sharpness, speed, and accuracy. Many factories use it to cut graphite into exact shapes for molds and other parts. It helps save time, reduce waste, and lower costs.

Endless Diamond Wire Types:

| Wire Type | Best Use |

| Full-Coated Endless Wire | For cutting graphite blocks, rods, and plates |

| Segment Coated Diamond Wire Loop | Mold and Carbon Cutting |

| Thread Coated Diamond Wire Loop | cut graphite into exact shapes for molds |

Why Choose Vimfun for Endless Diamond Wire

Vimfun is one of the top endless diamond-wire suppliers. They make spiral-coated, segmented, and connectable wires. Their products are strong, safe, and priced reasonably. They also give quick help to clients so they can find the correct wire. Whether you need sapphire, silicon, solar, or graphite wires, Vimfun is a name you can trust.

Endless diamond wire is the best tool for cutting hard stones. It lasts long, cuts smoothly, and makes work simple. It saves time, money, and waste while staying safe and easy to use.

FAQs

- Why is endless-diamond wire better than normal blades?

It lasts longer, cuts cleaner, and makes less waste. Normal blades wear down fast, but diamond wire stays sharp and safe.

- Can endless-diamond wire cut both sapphire and silicon?

There are special wires for each, but both are made strong. They can cut sapphire glass, silicon wafers, and other hard crystals.

- Where can I find affordable endless-diamond wire?

Brands like Vimfun offer low-cost wires that are safe and reliable. They also help customers choose the correct wire.

- Is diamond wire cutting safe for graphite?

Yes, it is safe if used the right way. The wire runs smoothly, makes less dust, and stays cool while cutting.

- How long does endless diamond-wire last?

It depends on the job, but good wires can last many hours of cutting. With good care, they stay sharp and safe for extended use.