The Segment Coated Diamond Wire Loop is a robust tool used in various industries. It helps cut through hard materials like concrete, metals, and stones. The wire has tiny diamonds affixed to it, which provides smooth and simple cutting. This wire operates in a closed loop, allowing it to move continuously without stopping. Factories and workshops like to use this wire because it saves time, cuts accurately, and lasts a long time. The wire is safe to use and helps workers make clean, precise cuts.

Durable Segment Coated Diamond Wire for Easy Cutting

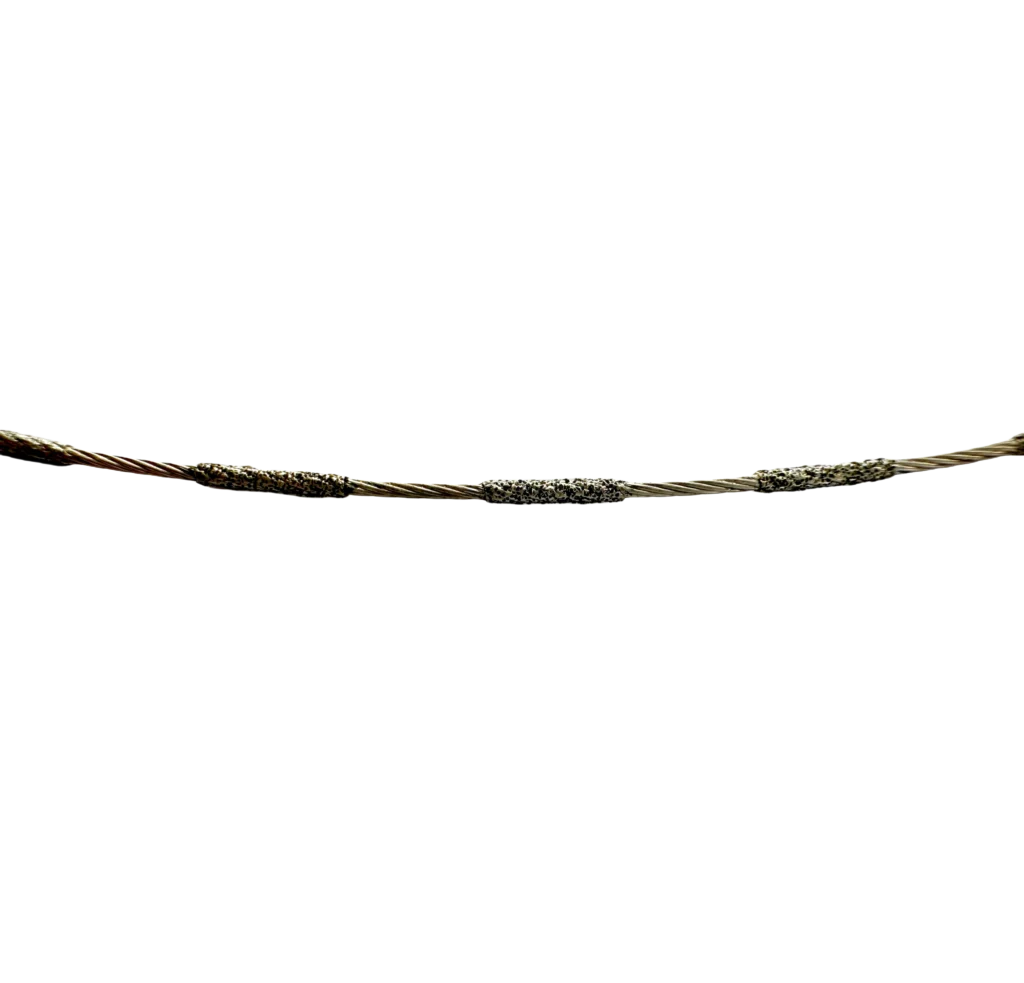

A segment-coated diamond wire loop is a type of endless diamond wire. Tiny diamonds are fixed on metal segments along the wire. The wire can easily cut through strong materials thanks to these diamonds. Electroplating is a process used for attaching the diamonds. This makes the wire very strong and long-lasting. It differs from standard wires in that it does not wear out quickly. This wire is also called an electroplated diamond wire loop. It is a handy tool for precise cutting in many industries.

Uses in Industry

The Segment Coated Diamond Wire Loop is used in many factories and workshops. Granite, marble, quartz, metals, and other hard materials may all be cut by it. Machines and wire saws use the wire to cut precisely. It works fast and saves materials. Industries such as construction, stone processing, mining, and electronics utilize this wire. The wire helps workers get smooth surfaces and exact shapes. It is one of the best tools for cutting hard materials safely and efficiently.

Advantages of Segment-Coated Diamond Wire Loop

This diamond wire loop has many advantages. It is strong, durable, and works for a long time. It cuts hard materials faster than standard tools. The electroplated diamonds have a longer lifespan and stay sharp. Because of its closed-loop process, the wire may cut continuously without halting. It reduces the effort needed and makes safer cuts. Workers can create clean and smooth surfaces. This wire is handy as a precision cutting tool for industries that require high-efficiency cutting solutions.

Segment Coated Diamond Wire Loop

The Segment Coated Diamond Wire Loop is a popular product for cutting hard materials. It is easy to use and works for many industrial jobs.

Features:

- Electroplated diamonds for strong cutting

- Endless diamond wire loop for continuous work

- Cuts hard materials like stones, quartz, and metals

- Saves time and improves cutting accuracy

This wire is compatible with diamond wire loop saws and other machines. It helps workers cut materials safely, smoothly, and with less waste. The product is very reliable and lasts a long time.

How a Segment-Coated Diamond Wire Loop Works

The wire loop works by moving over the material to cut it. The diamonds grind through hard surfaces without breaking them. This makes smooth cuts without chips. The wire moves in a continuous loop, forming a closed-loop diamond cutting system. The electroplated diamonds stay fixed on the wire and cut evenly. The tool provides precise results while saving industry money and time.

Maintenance and Care

Taking care of the Segment Coated Diamond Wire Loop is simple. Clean the wire to get clear of dust and dirt after using it. To prevent the wire from being loose or even breaking, check its tension on regularly. Avoid using excessive force and follow the recommended cutting speeds. Regular care makes the wire last longer. Proper maintenance ensures this precision cutting tool remains safe and effective for all industrial applications.

Comparison with Other Diamond Wire Loops

The Segment Coated Diamond Wire Loop is superior to many other wires. Electroplated diamond wires work well, but the segment-coated design lasts longer. Endless diamond wires are suitable for closed-loop cutting, but this wire remains sharp for a longer period. This wire is preferred by industries that need accurate cutting. Compared to standard diamond wire saws, it is reliable, secure, and saves time and resources.

Applications in Cutting Hard Materials

This wire loop is ideal for cutting through tough materials, including granite, marble, quartz, metals, and concrete. It may be used in small manual wire saws, automated systems, and machines. The wire cuts cleanly and smoothly. It helps reduce waste and saves time. This diamond cutting wire is a high-efficiency cutting solution. Industries that require precise shapes and smooth surfaces utilize this wire to achieve consistently better results.

Diamond Wire Loop Features

| Feature | Details |

| Type | Endless Diamond Wire |

| Cutting | Closed-loop diamond cutting |

| Materials | Granite, marble, quartz, metals |

| Durability | Long-lasting and sharp |

| Use | Machines and manual saws |

| Benefits | Safe, smooth, fast, accurate |

Buy the Strong Segment Coated Diamond Wire Loop

Do you need a reliable and secure tool to cut through hard materials? At Vimfun, we have the Segment Coated Diamond Wire Loop. Marble, quartz, metals, and stones are all readily cut by it. This tool is precise, easy to use, and safe. It helps you work more quickly and saves time. You can use it in diamond wire loop saws or other machines. It is strong, lasts a long time, and makes cutting easy. Get your Segment Coated Diamond Wire Loop from Vimfun today and make your work safe and straightforward.

The Segment Coated Diamond Wire Loop is a strong and safe tool for cutting hard materials. It works smoothly with small diamonds and can be used repeatedly. This wire helps industries cut faster, save time, and operate more efficiently.

FAQs

- What materials can it cut?

It can cut hard materials like granite, marble, quartz, metals, and concrete.

- Why is it better than standard cutting tools?

It is safer, lasts longer, works faster, and makes clean, smooth cuts with less waste.

- Can it be used in machines?

Yes, it works in diamond wire loop saws and other industrial cutting machines.

- How should I take care of it?

Clean the wire after use, check tension, and avoid using too much force to make it last longer.

- Who can use this wire loop?

Industries and workshops that cut hard materials like stone, metals, and concrete can use it.

- What are the main benefits?

It saves time, improves cutting accuracy, works safely, and lasts a long time.

- Is it easy to use?

Yes, it is simple to use and works smoothly for both machines and manual cutting.