SH60-R Rotary Diamond Wire Saw

The SH60-R is a high-capacity horizontal diamond wire saw designed for rotary cutting of large, hard, and brittle materials such as sapphire, quartz, ferrites, ceramics, and composite oxides. Its robust structure, powerful drive, and pneumatic tensioning system enable continuous wire rotation for smooth slicing and shaping of cylindrical or irregular workpieces.

Key Features

- Endless Diamond Wire Cutting

Utilizes a high-speed endless diamond wire system for stable, smooth, and chip-free cutting of fragile graphite materials. Low Kerf Loss, High Precision

Achieves clean slicing with kerf widths as narrow as 0.4 mm, minimizing material waste and reducing edge damage.- Ultra-Low Cutting Force

Abrasive cutting method reduces mechanical stress on delicate edges, preventing chipping or microfractures. - Simple Slice-Only Configuration

This machine is optimized for straight slicing only, ensuring maximum mechanical stability and throughput for high-volume production. Rotary Cutting Mode: Workpiece rotates continuously during cutting for smoother surface finish

Large Cutting Size: Supports up to Ø600 mm diameter × 500 mm height

High-Precision Construction: Flatness accuracy up to ≤ 0.1 mm, surface roughness ≤ Ra 0.8 μm

Heavy Load Capacity: 500 kg worktable with IP55-rated sealed structure

Endless Diamond Wire System: Smooth, closed-loop wire motion avoids vibration

Oil Cooling with Mist Collection: Prevents dust dispersion and ensures clean operation

Independent PLC System: Intuitive panel control, no external PC required

TECHNICAL SPECIFICATION

| Parameter | Value |

|---|---|

| Machine Dimensions | 1646 × 1733 × 2010 mm |

| Worktable Size | Ø600 mm |

| Max Cutting Area | Ø600 mm × 500 mm height |

| Travel Range | Ø635 mm × 505 mm |

| Cutting Accuracy (Flatness) | ≤ 0.1 mm |

| Surface Roughness | ≤ Ra 0.8 μm |

| Max Load Capacity | 500 kg |

| Main Motor Power | 0.75 kW, 2800 rpm |

| Wire Diameter | 0.35 – 0.8 mm |

| Wire Length | ~3710 mm |

| Wire Speed | Up to 84 m/s (adjustable) |

| Tension Method | Pneumatic |

| Drive Motor | Asynchronous motor |

| Drive Type | 4-motor drive |

| Control System | SHTC T30 PLC (independent operation) |

| Power Supply | Single-phase 220V / 50Hz |

| Installed Power | 3.2 kW |

| Dust & Mist Collection | Oil-cooled, mist-recycling system |

| Protection Grade | IP55 |

| Machine Weight | Approx. 1250 kg |

VIDEO SHOWCASE

COMPARISON OF THE CUT SURFACE EFFECT

TECHNOLOGY COMPARISON

Rotary Diamond Wire Cutting vs. Flat Slicing and Blade Systems

For large and dense ceramic or magnetic components, conventional cutting methods often fail:

Flat slicing causes uneven pressure and surface distortion

Blades introduce microcracks and are prone to quick wear

EDM systems are slow and can’t process non-conductive materials

The SH60-R’s rotary design allows:

Constant wire-to-material contact and uniform force distribution

Continuous cutting across all angles without stopping rotation

Cleaner edges, reduced stress, and longer consumable life

This makes it the optimal solution for cutting round, curved, or cylindrical hard materials.

TYPICAL APPLICATIONS OF THIS GRAPHITE BOAT CUTTING MACHINE

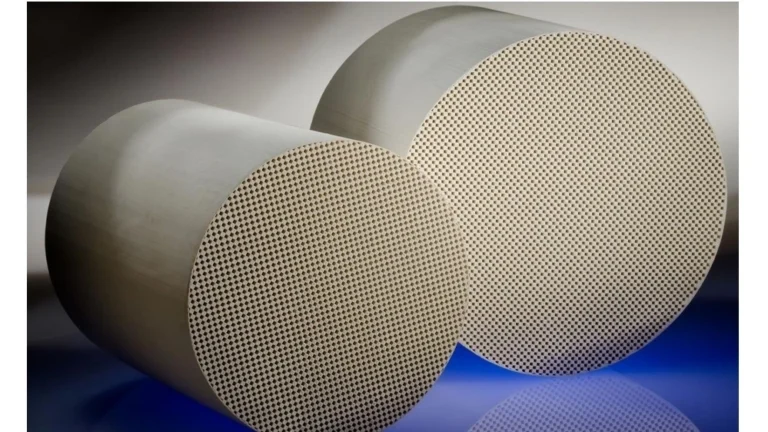

Ferrite Magnetic Cylinders

Cutting round ferrite magnets for industrial motors, sensors, and transformers

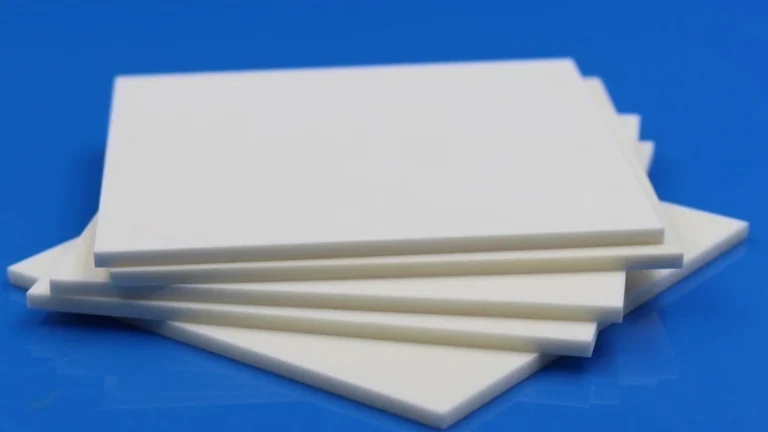

Alumina Ceramic Rods

Shaping insulation-grade alumina cylinders for power electronics

PZT Piezoelectric Blanks

Rotary slicing of piezoelectric blocks for high-performance actuator production

Sapphire and Quartz Tubes

Processing precision sapphire and quartz materials for optics and photonics

Composite Ceramics and Oxides

Cutting large hybrid materials in aerospace and defense applications

PRODUCT AVAILABILITY NOTICE

The equipment models listed on this website represent only a selection of our full product range.

For each type of diamond wire slicing machine or semiconductor cutting equipment, we offer larger sizes, custom configurations, and application-specific designs based on customer needs.

If your material, size, or process requirements are not covered by the listed products, please contact us directly. Our engineering team will recommend or customize the most suitable solution for your application.

WHY CHOOSE US

High-Speed Endless Wire Cutting

High-Rigidity Cast Structure

High-Precision Guide Rails and Ball Screw

Automatic Constant-Tension System

Micron-Level Feed Control

User-Friendly Smart Interface

Fully Enclosed Protective Design (Optional)

Low Maintenance & Cost Efficiency

Modular Design

Low Maintenance & Cost Efficiency

Automatic Lubrication System

Customer Testimonials

Semiconductor Material Cut

Frequently Asked Questions

What is the maximum thickness the machine can handle for cutting?

What is the difference between this wire saw and BAND SAW?

The cutting speed would be similar, but wire saw’s cut surface quality is far more better. and the kerf loss is smaller.