Got tough materials to cut? It’s a pain, right? Many tools just can’t handle it; they break, bend, and leave jagged edges. That’s where diamond cutting wire loops come in super handy. They make quick, clean, spot-on cuts every single time. Many industries are switching to these loops because they save time and improve the quality of work. Let’s check out what they’re all about, how they do their thing, and why they’re so important for the cuts you need.

High-Performance Diamond Wire Loops

These diamond wire loops make it way simpler to cut strong materials. They give you smooth, fast, and clean cuts, without the headache. Two popular types are:

Field-Connectable Diamond Wire Loop

Field-Connectable Diamond Wire Super helpful when you need to make the loop right on the spot. You can change the length and feed the wire through tight spots, holes, and inner areas before locking the loop. Great for cutting shapes inside things, big shapes, and large parts. It gives you more control and makes tricky jobs easier.

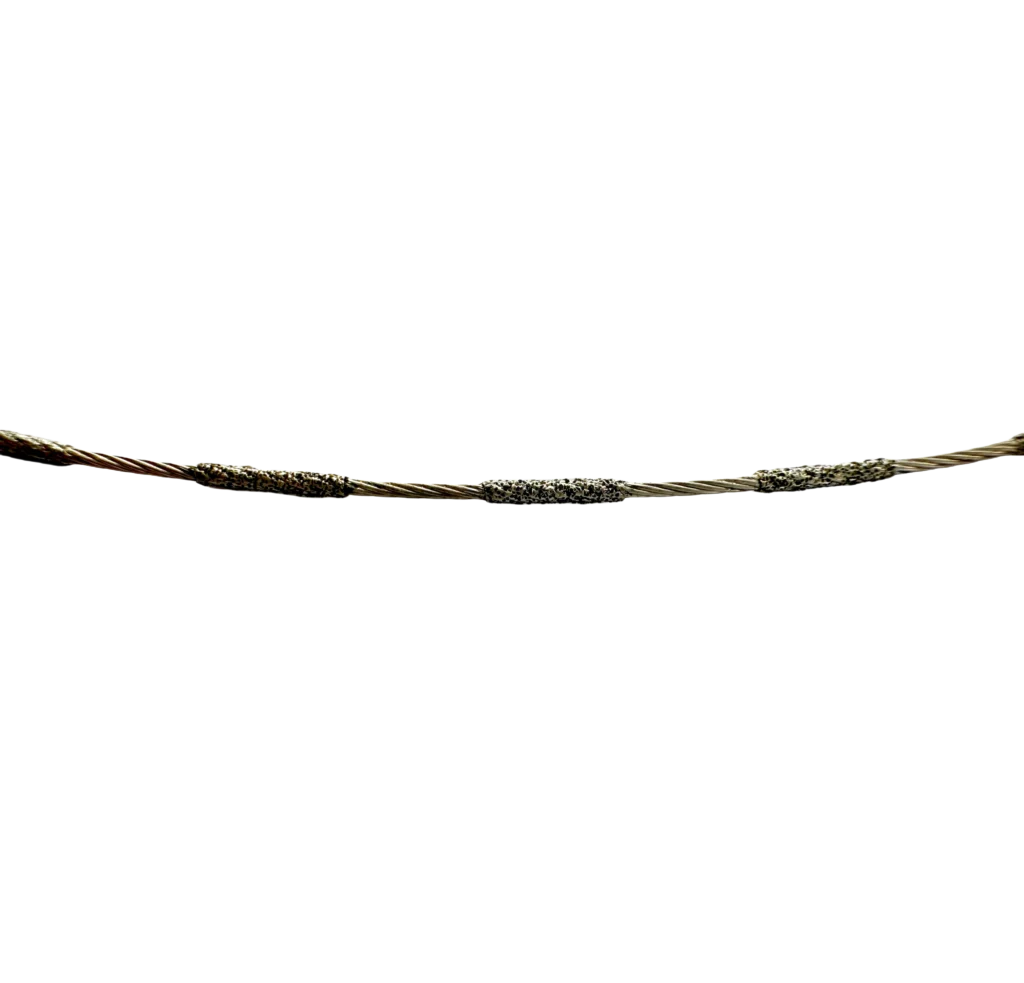

Full-Coated Endless Wire

This Full-Coated Endless is a wire loop that is closed and completely covered in diamond bits. It’s strong, smooth, and cuts with consistent power since it’s closed and solid. The wire can slice through lots of stuff that’s not as hard as diamond, leaving clean edges behind. It’s a solid pick for everyday jobs where you need reliable performance.

What’s a Diamond Cutting Wire Loop Anyway?

It’s simply a thin wire shaped into a loop and coated with tiny diamond bits. Diamonds are the hardest substance around, so they easily slice through other hard materials. The precision diamond cutting wire loop design keeps the wire running smoothly on machines without stopping. As the loop spins, the diamond grains scrape and slice the material with crazy control, giving you super clean cuts. People use diamond wire loops when they need the most accuracy, especially in fields that work with touchy materials.

How Diamond Wire Loops Deliver Fast and Clean Cuts

Diamond wire loops are speedy because diamonds take away material fast without pressure. The endless diamond wire loop keeps a steady pace, and the diamond outer layer makes sure the cut stays smooth. Since the wire cuts gently, it doesn’t hurt the material. You also get less heat, which is vital for many things. Less heat means a clean surface with fewer chances of breaks. So, diamond wire loops are much cleaner than regular blades.

Features of Industrial diamond cutting wire

Our diamond cutting wire loops bring strong performance and long life to the table. We use top-notch diamond grains, which boost cutting speed and cut down on wear and tear. The Diamond abrasive wire loop itself is tough and bendy, so it won’t snap. We make each loop to keep a stable tension, which keeps every cut spot-on. They also fight off rust and heat, making them safe to use in a variety of places. All these things help beginners and pros work with ease and confidence.

Materials and Technology Behind High-Precision Cutting

Diamond cutting wire loops are amazing because they’re made with advanced materials and modern tech. The diamond abrasive wire loop inside is usually built from strong metals like steel. The diamonds attached to the wire are chosen from industrial-grade materials. These diamonds are seriously sharp and the same size, which helps keep the cut consistent. The way they stick the diamonds on keeps them in place, even if you’re cutting for a long time. Also, fancy new ways of making the wire smoother help it glide better and cut faster.

Industries That Use Diamond Cutting Wire Loops

Lots of industries rely on diamond cutting wire loops. The computer chip industry uses them to slice silicon wafers super thin and clean. The tech field uses them for cutting glass and other clear materials. The ceramics industry uses them to cut hard blocks easily. You’ll also find them in solar panel plants, labs, and art studios for creative projects. All of these industries pick diamond wire loops because they need perfect cuts with zero mess. Companies, like Vimfun, create top-quality machines that work with these loops; they’re a big name in making machines that handle these materials.

Why choose our high-precision diamond slicing wire?

Using the right diamond loop saw wire can make your work so much better. Our loops are made for accuracy, so you get exactly the cut you’re after every time. You’ll also save time because the wire cuts fast and easily. And since the loops are durable, you won’t have to swap them out often. This saves you cash and keeps your machines running. Also, the loops play nicely with all sorts of materials, so you can use one loop for lots of different jobs.

Performance Benefits: Speed, Accuracy, and Durability

One of the best things about using a diamond cutting wire loop is the speed. The diamonds slice well and take material away fast. This helps you wrap up your work way faster. Accuracy is another huge plus. The wire stays straight and doesn’t wobble, so the cuts come out looking clean and even. And they stand the test of time because diamonds are super tough and don’t wear out quickly. All this means the loop keeps getting the job done for hours.

Custom Sizes and Specifications Available

We do custom sizes and options for our diamond cutting wire loops. You can pick different thicknesses, lengths, and diamond grain sizes. Need a beefier wire for tough stuff? We can make that. Need a thinner wire for delicate work? We can handle that too. Custom loops help you nail the perfect cut, cut down on waste, and boost your whole workflow. This is useful for little shops and big factories.

How to Use Diamond Cutting Wire Loops Safely and Efficiently

It’s simple to use a diamond cutting wire loop, but you need to take safety seriously to keep yourself and your diamond wire loop cutter safe. First, make sure the loop is installed on the machine the right way. A loose wire can slip, and a tight wire can snap. Keep your work area clean and dry; this helps the wire move without a problem. Also, use the right cutting speed: too fast can cause heat, and too slow wastes time. Wear safety glasses, of course. After each cutting job, look over the wire for any damage.

Where to Buy Diamond Cutting Wire Loops

If you’re looking for diamond cutting wire loops, get them from a company with a good reputation. Look for someone who offers strong materials, good tech, and solid customer service. Vimfun is a trusted source for these goods. When you pick Vimfun, you get tools that offer speed, accuracy, and long life. They make sure you get the best cutting performance.

FAQs

What’s a diamond cutting wire loop?

It’s a wire covered in diamond bits used for cutting materials.

Why are these loops better than blades?

They cut faster, cleaner, and with less damage.

What materials do they cut?

These can cut silicon, glass, ceramics, and other tough stuff.

How long do they last?

They last a long time because diamonds don’t wear down fast.

Where can I buy them?

You can buy them from reliable places like Vimfun, which are known for precision cutting tools.