Cutting complex shapes with speed and accuracy isn’t easy. That’s why many industries today rely on advanced multi axis contour cutting machines. These smart machines are made to handle tricky shapes and detailed designs. Whether it’s foam, plastic, or even semiconductor materials, these machines deliver super performance.

So, what makes them so special? The answer is in the word “multi-axis.” Unlike basic cutters, these advanced foam contour cutting systems move in several directions at once. That means they can cut curves, corners, and angles with perfect control.

We’ll explore how these machines work, what materials they cut, and how they help different industries.

Precision Multi Axis Contour Cutting Machine Types

There are different kinds of high-speed multi-axis slicing machines, and each type has its own job. One common type is the 2-axis cutter. It moves in two directions, usually left to right and up and down. This is great for simple cuts like blocks and slices.

There’s the 3-axis cutter. This adds another direction of movement, usually forward and backward. Now the machine can make curves and rounded shapes. That’s great for foam shapes used in packaging or decoration.

For even more detailed work, there’s the 4-axis or 5-axis cutting machine. These can move in every direction. They can twist, turn, and tilt while cutting. This lets them create very complex shapes like those used in car seats, aeroplane parts, and even medical tools.

Some machines are fully automatic. They follow digital designs with no help needed. Others are semi-automatic, which means a worker sets them up first. Both kinds offer high accuracy and strong performance.

How Multi-Axis Technology Boosts Cutting Precision

Precision is key when cutting detailed designs. And multi axis contour cutting machine makes that possible. But how?

It starts with the way the machine moves. With more axes, the machine can move in more directions. This means it can follow a shape exactly, even if that shape twists or turns. Simple machines might only cut straight lines. But multi-axis machines can cut curves, circles, and 3D shapes—all with clean edges.

Another way precision is improved is through digital control systems. These machines are often connected to computers that use CAD or CAM software. This software tells the machine how to cut, step by step. It leaves no room for mistakes.

These 3D shape cutting machines are made from high-quality parts that don’t shake or wobble. That helps keep the wire or blade steady during cutting. When the wire stays still, the cut stays perfect.

Top Features That Deliver Super Performance

A multi axis contour cutting machine stands out because of its special features. These features make it strong, fast, and easy to use.

- One big feature is the servo motor system. These motors are super accurate. They help the machine move smoothly and stop right on time. That’s how it cuts detailed parts without any slip-ups.

- Next is the digital controller or touch-screen panel. With this, workers can set the design, speed, and depth in just a few steps. Some even let you save and repeat old jobs, making it very user-friendly.

- Many machines also come with a high-tension wire system. This keeps the cutting wire tight and straight. That helps in cutting thick or soft materials without sagging.

- Cooling systems are also important. Some machines have built-in fans or water systems to keep the wire and material cool. This avoids burning or melting during the cut.

- And don’t forget about safety features. Modern machines come with covers, sensors, and auto-stop systems. These protect the user and make the machine safe for any workspace.

Materials Ideal for Multi-Axis Contour Cutting

These machines are constructed to reduce many types of substances. Thanks to their smart design, they take care of both tender and difficult gadgets effortlessly.

Foam is one of the maximum common substances. Whether it’s smooth foam for cushions or stiff foam for insulation, these machines reduce it cleanly. The foam doesn’t tear, stretch, or melt.

Plastics are also smooth to cut. From thin sheets to thick blocks, plastic may be fashioned without cracks or burns.

In the semiconductor industry, those machines are used to cut silicon, ceramic, and other sensitive materials. These ought to be reduced with wonderful care, and multi-axis machines make it viable.

You can also reduce rubber, styrofoam, fibreglass, or even composite materials. That makes those machines top-quality and beneficial for different styles of businesses.

Industries that benefit from CNC multi-axis cutting equipment

Lots of industries now use multi axis contour cutting machines because they offer fast, clean, and exact results.

In the semiconductor industry, those machines assist in reducing wafers, chips, and other sensitive components. These elements ought to be the best, and precision reduction is a must.

The packaging industry uses those machines to shape foam inserts that shield merchandise at some point in shipping. Each insert should match the form of the product, and those machines make that viable.

In the car and aerospace industries, components like seat cushions and protection pads are formed by the use of contour reducing. The curves and angles must be in shape flawlessly, or the parts received’t work.

Even the furniture industry uses them to form armrests, headboards, and cushions. And in clinical labs, they help make equipment and smoothies for patients.

Choosing the right computer-controlled Contour Cutter

Picking the right precision contour foam cutter takes a few questions. Observe the sort of paintings you do. If you simply reduce simple shapes, a 2-axis gadget can be sufficient. But for advanced designs, choose a 3-axis, 4-axis, or 5-axis machine.

Think about the substances you operate. Softer substances like foam require a distinctive setup from tougher ones like plastic or ceramic. Make sure the machine you choose can cope with your materials without damage.

Check the cutting size. Some machines are small and perfect for short runs. Others are big and made for large sheets or blocks. Choose one that fits your workspace and your job size.

Don’t forget to look at speed and software options. Machines with good software are easier to use. They also help you repeat jobs quickly.

And most importantly, choose a machine that offers strong support and training. If you’re new to contour cutting, getting help from the maker is a big plus.

Good Manufacturer of Industrial multi-directional cutting machines

If you want the best, choose Vimfun.

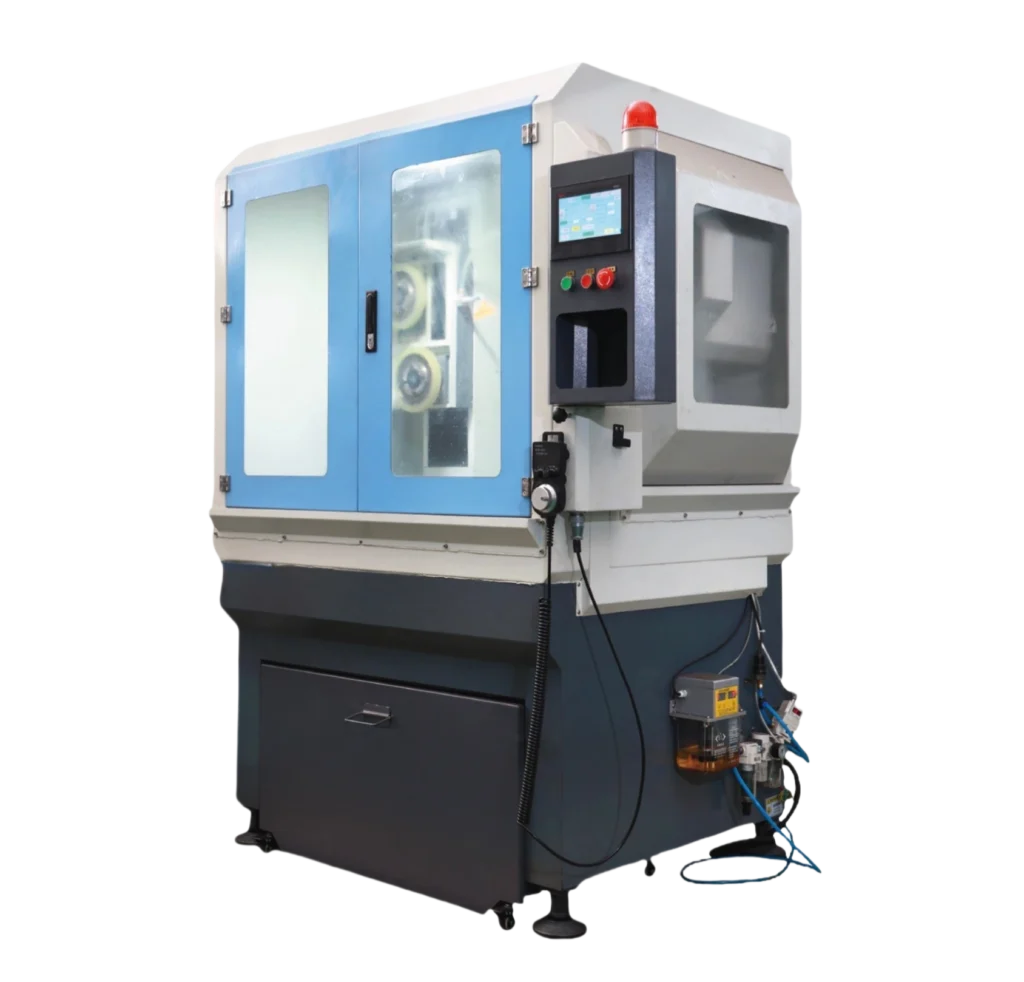

Vimfun is a trusted expert in precision cutting for semiconductor materials. They design and build high-quality multi axis contour cutting machines that deliver true super performance. Their machines are known for their strength, speed, and accuracy.

Their machines are smooth to use and built to the ultimate. They include smart features like virtual controls, servo automobiles, and robust safety structures. Whether you are reducing foam, plastic, or sensitive substances like silicon, Vimfun has a device that suits your needs.

Not handiest that, but they provide outstanding customer support. They help you learn how to use the device, resolve troubles, and get the quality effects. Their crew knows the way to serve industries where every cut ought to be ideal.

You can go to their website to see their complete variety of machines, take a look at opinions, and purchase online with confidence. When you select Vimfun, you are deciding on first-rate, overall performance, and peace of mind.