SG20 Precision Slicing Machine for Semiconductor Materials

The SG20 is a high-precision diamond wire slicing machine designed for cutting hard and brittle semiconductor materials into ultra-thin slices. With programmable slicing control and stable gantry structure, it delivers excellent accuracy and surface quality. Ideal for sapphire, alumina, silicon carbide, and piezoelectric ceramic wafer slicing, SG20 supports automated slicing tasks down to 0.1 mm thickness with minimal chipping.

Key Features

🔹 Ultra-Thin Slicing: Supports slice thickness from 0.1 mm and up

🔹 Fully Programmable: Set custom thickness for each slice via CNC control

🔹 High Precision: Positioning accuracy ±0.01 mm; surface roughness ≤ Ra 60

🔹 Stable Gantry Structure: Ensures long-term accuracy and vibration reduction

🔹 Compatible with Hard Materials: Perfect for SiC, sapphire, alumina, etc.

🔹 Servo Tensioning System: Stable wire tension for consistent cuts

🔹 User-Friendly Interface: PLC control with touchscreen operation

SG20 TECHNICAL SPECIFICATION

| No. | Name | Specification |

| 1 | Maximum Workpiece Length (mm) | 200 |

| 2 | Maximum Workpiece Width (mm) | 200 |

| 3 | Maximum Workpiece Height (mm) | 220 |

| 4 | Worktable Y-Axis Travel (mm) | 200 |

| 5 | Worktable Z-Axis Travel (mm) | 220 |

| 6 | Maximum Diamond Wire Speed (m/s) | 58 |

| 7 | Minimum Feed Increment Y-Axis (mm) | 0.01 |

| 8 | Minimum Feed Increment Z-Axis (mm) | 0.01 |

| 9 | Repeat Positioning Accuracy Y-Axis (mm) | 0.01 |

| 10 | Repeat Positioning Accuracy Z-Axis (mm) | 0.01 |

| 11 | Total Power Consumption (kW) | 1.5 |

| 12 | Power Supply | 220V 50Hz |

| 13 | Machine Size(mm) | 1044*943*1810 |

| 14 | Machine Weight(kg) | 400 |

TYPICAL APPLICATIONS

Slicing sapphire rods into wafers for LED and optoelectronic devices

Cutting alumina ceramic cylinders for substrate and sensor packaging

Processing silicon carbide for power electronics

Wafering piezoelectric ceramics for acoustic and sensor applications

Ultra-thin slicing of quartz and other hard non-metals

VIDEO SHOWCASE

Slicing REXOLITE Blocks (0.5 mm Thick)

This video shows the SG20 slicing machine in action at a client site, cutting Rexolite—a high-performance plastic commonly used in semiconductor and microwave applications. The machine achieves stable slicing at 0.5 mm thickness, demonstrating its ability to deliver clean, consistent, and ultra-flat surfaces on non-metallic materials.

Cutting Piezoelectric Ceramics (0.2 mm Slice)

Watch how the SG20 precisely slices fragile piezoelectric ceramics to 0.2 mm thickness without cracking or edge chipping. This level of performance is critical for sensors, actuators, and other precision semiconductor components that require ultra-thin slicing with minimal surface stress.

CUTTING METHOD COMPARISON

When processing hard and brittle semiconductor materials, manufacturers have traditionally relied on EDM (Electrical Discharge Machining), spool-type diamond wire saws, and ID saws (Inner Diameter Blades). However, these methods often face major limitations:

⚠️ EDM Cutting

Extremely slow and limited to conductive materials only. Not suitable for ceramics, sapphire, or quartz.⚠️ Spool Diamond Wire Saws

The back-and-forth motion results in low cutting speeds, wire vibration, and uneven surfaces.⚠️ Inner Diameter Saws (ID Saws)

Blade size restricts the maximum workpiece dimensions and limits flexibility. Tool wear is high, and replacement is costly.

✅ Endless Diamond Wire Slicing Machines like the SG20 offer:

Fast, stable cutting with no reciprocation

Minimal vibration for high surface quality

Capability to handle ultra-thin slicing (down to 0.1 mm)

Compatibility with both conductive and non-conductive materials

Lower maintenance cost and easier wire replacement

This makes the SG20 an ideal solution for cutting semiconductor materials such as sapphire, silicon carbide, alumina, and piezoelectric ceramics.

TYPICAL APPLICATIONS

Sapphire Wafer Production

Slicing sapphire rods into ultra-thin wafers for LED, optical, and power device applications

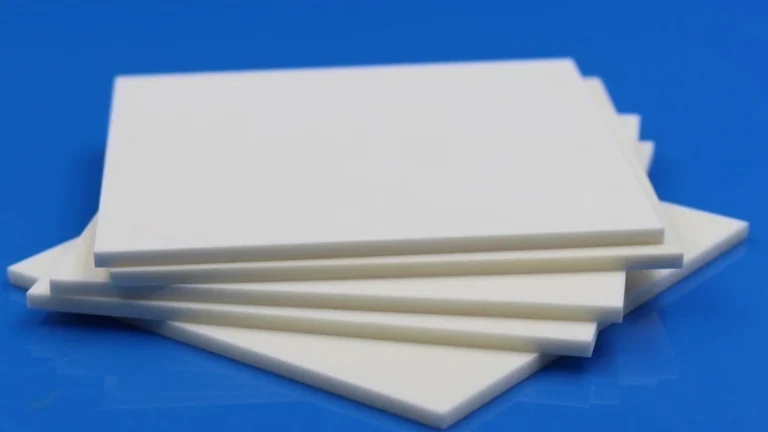

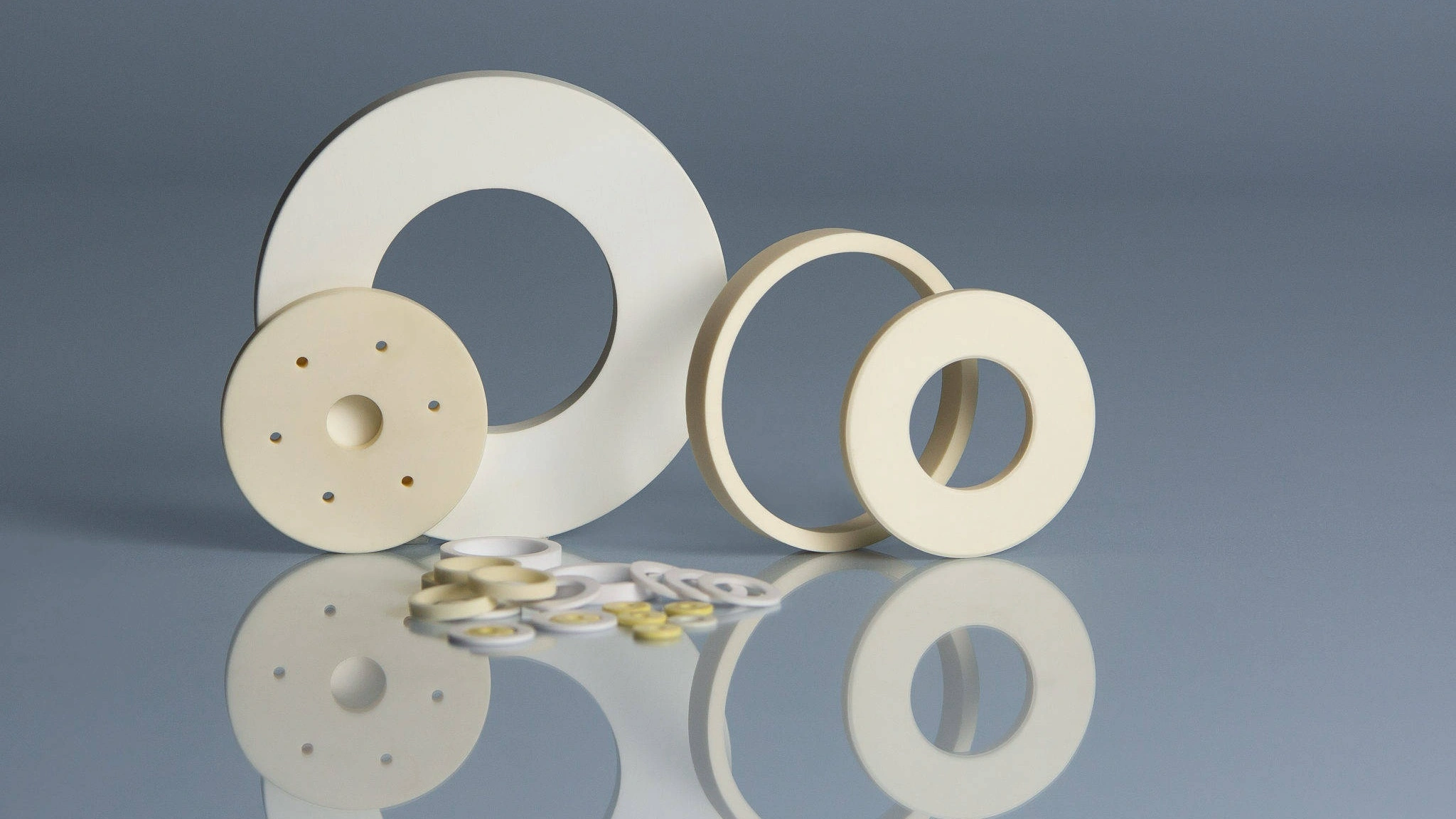

Alumina Ceramic Substrates

Cutting high-density ceramic cylinders into thin sheets for packaging, sensors, and insulators

Silicon Carbide Blocks

Preparing SiC components for power semiconductors, thermal spreaders, and advanced modules

Piezoelectric Ceramics

Slicing PZT and similar materials into precision elements for actuators, MEMS, and transducers

Quartz & Optical Glass

Producing clean, chip-free wafers for photonics, optics, and advanced research applications

CUSTOM MODELS AVAILABLE

The slicing machines and diamond wire saws listed on this website represent only a portion of our full product line. For each model—such as the SG20—larger versions are available to accommodate bigger workpieces and higher throughput requirements.

In addition to the standard equipment shown here, Vimfun also offers:

🔧 Custom-built semiconductor cutting machines

📏 Extended travel and load capacity options

🔁 Special slicing functions for unique material types

🎯 Tailored multi-axis configurations for complex geometries

If you’re working with non-standard material sizes or require specific process capabilities, please contact us directly. Our technical team will help you identify or customize the most suitable slicing solution for your application.

WHY CHOOSE US

High-Speed Endless Wire Cutting

High-Rigidity Cast Structure

High-Precision Guide Rails and Ball Screw

Automatic Constant-Tension System

Micron-Level Feed Control

User-Friendly Smart Interface

Fully Enclosed Protective Design (Optional)

Low Maintenance & Cost Efficiency

Modular Design

Low Maintenance & Cost Efficiency

Automatic Lubrication System

Customer Testimonials

Frequently Asked Questions

What is the maximum thickness the machine can handle for cutting?

What is the difference between this wire saw and BAND SAW?

The cutting speed would be similar, but wire saw’s cut surface quality is far more better. and the kerf loss is smaller.