SGI20 Contour Cutting Machine

The SGI20 is a high-precision diamond wire cutting machine specially designed for contour cutting of complex profiles in hard and brittle semiconductor materials. With full CNC control and support for importing CAD drawings, it enables automatic execution of curved, angled, and irregular shapes with exceptional accuracy.

KEY FEATURES

CAD-Compatible Profile Cutting: Import DXF or other CAD files to execute custom geometries

±0.01 mm Positioning Accuracy: High repeatability for detailed patterns

Multi-Axis Contour Control: Synchronized movement in Y and Z axes

Wide Material Compatibility: Suitable for sapphire, ceramics, quartz, SiC, and more

Automatic Slicing or Shaping: Choose between straight slicing or profile cutting modes

Precision Wire Tensioning System: Ensures consistent cutting performance

Small Footprint, Lab-Ready: Compact design fits well in R&D and cleanroom environments

TECHNICAL SPECIFICATION

| Parameter | Value |

|---|---|

| Worktable Dimensions | 200 × 200 mm |

| Worktable Travel (Y/Z) | 200 × 200 mm |

| Max Cutting Thickness | 200 mm |

| Max Product Size | 200 × 200 × 200 mm |

| Load Capacity | 50 kg |

| Positioning Accuracy | ±0.01 mm |

| Surface Roughness | ≤ Ra 60 |

| Wire Diameter | 0.3 – 0.65 mm |

| Drive System | Servo |

| Tensioning Method | Servo Tensioning |

| Control System | CNC |

| Broken Wire Protection | Yes |

| Max Wire Speed | 4800 RPM |

| Power Supply | Single-phase 220V / 50Hz ±10% |

| Installed Power | 1.5 kW |

| Machine Dimensions | 1044 × 943 × 1810 mm |

| Machine Weight | 560 kg |

VIDEO SHOWCASE

TECHNOLOGY COMPARISON

Traditional methods like CNC milling and laser cutting struggle with hard brittle materials due to:

High mechanical stress or thermal damage

Poor surface quality and material loss

Limitations in cutting complex contours cleanly

The SGI20 contour wire saw eliminates these issues by:

Using vibration-free endless diamond wire

Supporting fully automated CAD-profile cutting

Maintaining ultra-smooth finishes with no heat-affected zone

Offering precise, low-loss cutting for non-conductive, high-value materials

It’s the superior solution for engineers working with irregular ceramic or crystal profiles in the semiconductor field.

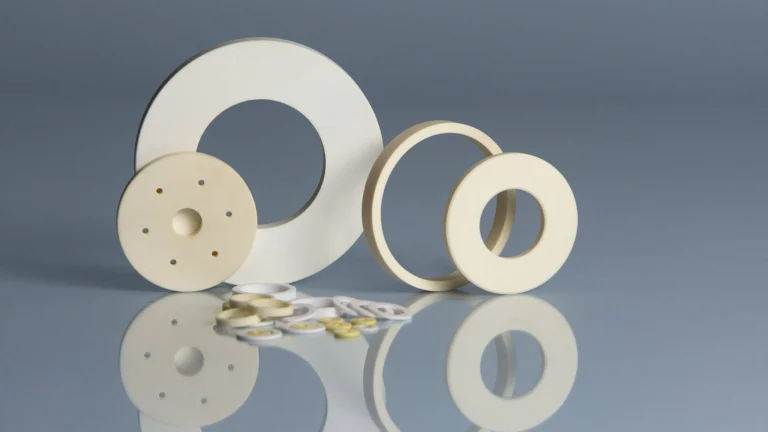

TYPICAL APPLICATIONS

Alumina Micro Housings

Profile cutting of complex ceramic shells for sensor, IC, and MEMS component encapsulation

PZT Actuator Geometries

Forming asymmetric or contoured piezoelectric elements for motion control and sensing devices

Sapphire Light Guide Structures

Precision shaping of prismatic and arc-shaped sapphire parts for photonics and infrared optics

Silicon Carbide Support Frames

Cutting non-linear support geometries for high-power SiC-based modules and RF substrates

PRODUCT AVAILABILITY NOTICE

The equipment models listed on this website represent only a selection of our full product range. For each type of diamond wire slicing machine or semiconductor cutting equipment, we offer larger sizes, custom configurations, and application-specific designs based on customer needs.

If your material, size, or process requirements are not covered by the listed products, please contact us directly. Our engineering team will recommend or customize the most suitable solution for your application.

WHY CHOOSE US

High-Speed Endless Wire Cutting

High-Rigidity Cast Structure

High-Precision Guide Rails and Ball Screw

Automatic Constant-Tension System

Micron-Level Feed Control

User-Friendly Smart Interface

Fully Enclosed Protective Design (Optional)

Low Maintenance & Cost Efficiency

Modular Design

Low Maintenance & Cost Efficiency

Automatic Lubrication System

Customer Testimonials

Frequently Asked Questions

What is the maximum thickness the machine can handle for cutting?

What is the difference between this wire saw and BAND SAW?

The cutting speed would be similar, but wire saw’s cut surface quality is far more better. and the kerf loss is smaller.