SGRT20 4-Axis for 3D Semiconductor Profile Cutting

The SGRT20 is a high-precision 4-axis diamond wire cutting machine built for the most complex 3D cutting tasks in semiconductor and advanced ceramic manufacturing. It enhances the SGR20 platform by adding a tilting rotary axis, enabling compound-angle and multi-surface cutting in full 3D space. This makes it ideal for producing complex structures with precision surfaces, tight tolerances, and minimal material loss.

KEY FEATURES

4-Axis Motion: X, Y, rotary, and tilting axes for true 3D profile cutting

Tilting Rotary Table: Enables compound-angle cuts and advanced geometry shaping

±0.01 mm Positioning Accuracy: High precision for demanding applications

Full CNC Programmability: Supports custom profiles from CAD or G-code

Suitable for Ultra-Hard Materials: Cuts sapphire, SiC, PZT, alumina, and more

User-Friendly PLC Interface: Intuitive control and multi-step automation

Modular Design: Custom jigs and workpiece holders available upon request

TECHNICAL SPECIFICATION

| Parameter | Value |

|---|---|

| Worktable Dimensions | 200 × 200 mm |

| Worktable Travel (Y/Z) | 200 × 200 mm |

| Max Cutting Thickness | 200 mm |

| Max Product Size | 200 × 200 × 200 mm |

| Load Capacity | 300 kg |

| Positioning Accuracy | ±0.01 mm |

| Surface Roughness | ≤ Ra 60 |

| Wire Diameter | 0.3 – 0.65 mm |

| Drive System | Servo + Stepper |

| Tensioning Method | Servo Motor Tensioning |

| Rotary Axis Type | Programmable Rotary |

| Tilting Angle | 0 – 25° |

| Control System | PLC |

| Broken Wire Protection | Yes |

| Max Wire Speed | 4500 RPM |

| Power Supply | Single-phase 220V / 50Hz ±10% |

| Installed Power | 1.5 kW |

| Machine Dimensions | 1044 × 943 × 1810 mm |

| Machine Weight | 580 kg |

VIDEO SHOWCASE

TECHNOLOGY COMPARISON

In semiconductor and advanced ceramics industries, several types of cutting equipment offer tilt-angle capability. Below is a professional comparison of four commonly used systems:

1. 5-Axis or Multi-Axis CNC Machining Centers

Control X/Y/Z plus A (rotation) and B (tilting) axes

Typically used for milling, engraving, and drilling of hard metals and plastics

Not ideal for brittle materials like ceramics or sapphire due to tool vibration

High equipment cost and large footprint

2. Multi-Axis Diamond Wire Cutting Machines (e.g. SGRT20)

Uses endless diamond wire for smooth, vibration-free cutting

Ideal for sapphire, silicon carbide, PZT, alumina, and other brittle materials

Supports programmable tilting from 0–25°, perfect for 3D contouring

High precision, minimal kerf width, and low material loss

3. Tiltable Inner Diameter (ID) Saws

Some ID saws allow minor tilt adjustment for angled cuts

Mainly used for edge chamfering or beveling in wafer processing

Limited by blade diameter and workpiece size

Less flexible for thick or nonstandard shapes

4 Laser Cutting Systems with 3D Tilt Control

Enables bevel cutting or contour shaping of thin substrates or wafers

Limited by optical path geometry and focusing system

Not suitable for thick blocks or hard brittle materials

May cause thermal damage, discoloration, or microcracks

SGRT20 Advantage

SGRT20 Advantage

Compared to the above technologies, the SGRT20 4-axis tilting diamond wire saw is uniquely positioned for:

Multi-surface shaping of brittle materials

Compound-angle slicing without thermal damage

Cutting non-conductive, hard materials with ultra-low edge chipping

Full 3D control in a compact and cost-effective platform

If your application involves angled cuts on fragile semiconductor materials, the SGRT20 is the optimal solution for both performance and precision.

TYPICAL APPLICATIONS

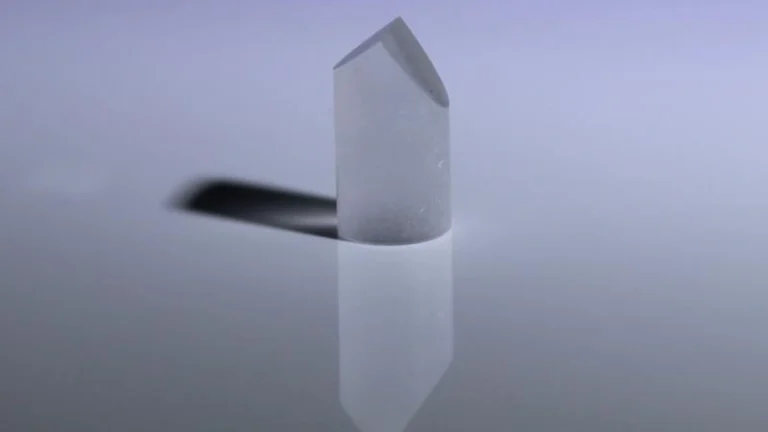

Prismatic Sapphire Structures

Cutting multi-surface sapphire prisms and windows for lasers, optics, and infrared imaging

Tilted PZT Ceramic Blocks

Forming compound-angle piezoelectric parts for advanced sensors and ultrasonic devices

Alumina Connector Bases

Shaping high-density ceramic housings for high-frequency and power device packaging

Custom SiC Substrates

Precision shaping of angled silicon carbide substrates for power module mounting

Aerospace-Grade Ceramic Assemblies

Cutting intricate ceramic composite parts with inclined and rotating geometries

PRODUCT AVAILABILITY NOTICE

More Models and Custom Solutions Available

The equipment models listed on this website represent only a selection of our full product range. For each type of diamond wire slicing machine or semiconductor cutting equipment, we offer larger sizes, custom configurations, and application-specific designs based on customer needs.

If your material, size, or process requirements are not covered by the listed products, please contact us directly. Our engineering team will recommend or customize the most suitable solution for your application.

WHY CHOOSE US

High-Speed Endless Wire Cutting

High-Rigidity Cast Structure

High-Precision Guide Rails and Ball Screw

Automatic Constant-Tension System

Micron-Level Feed Control

User-Friendly Smart Interface

Fully Enclosed Protective Design (Optional)

Low Maintenance & Cost Efficiency

Modular Design

Low Maintenance & Cost Efficiency

Automatic Lubrication System

Customer Testimonials

Frequently Asked Questions

What is the maximum thickness the machine can handle for cutting?

What is the difference between this wire saw and BAND SAW?

The cutting speed would be similar, but wire saw’s cut surface quality is far more better. and the kerf loss is smaller.

SGRT20 Advantage

SGRT20 Advantage